The Dodo Blog

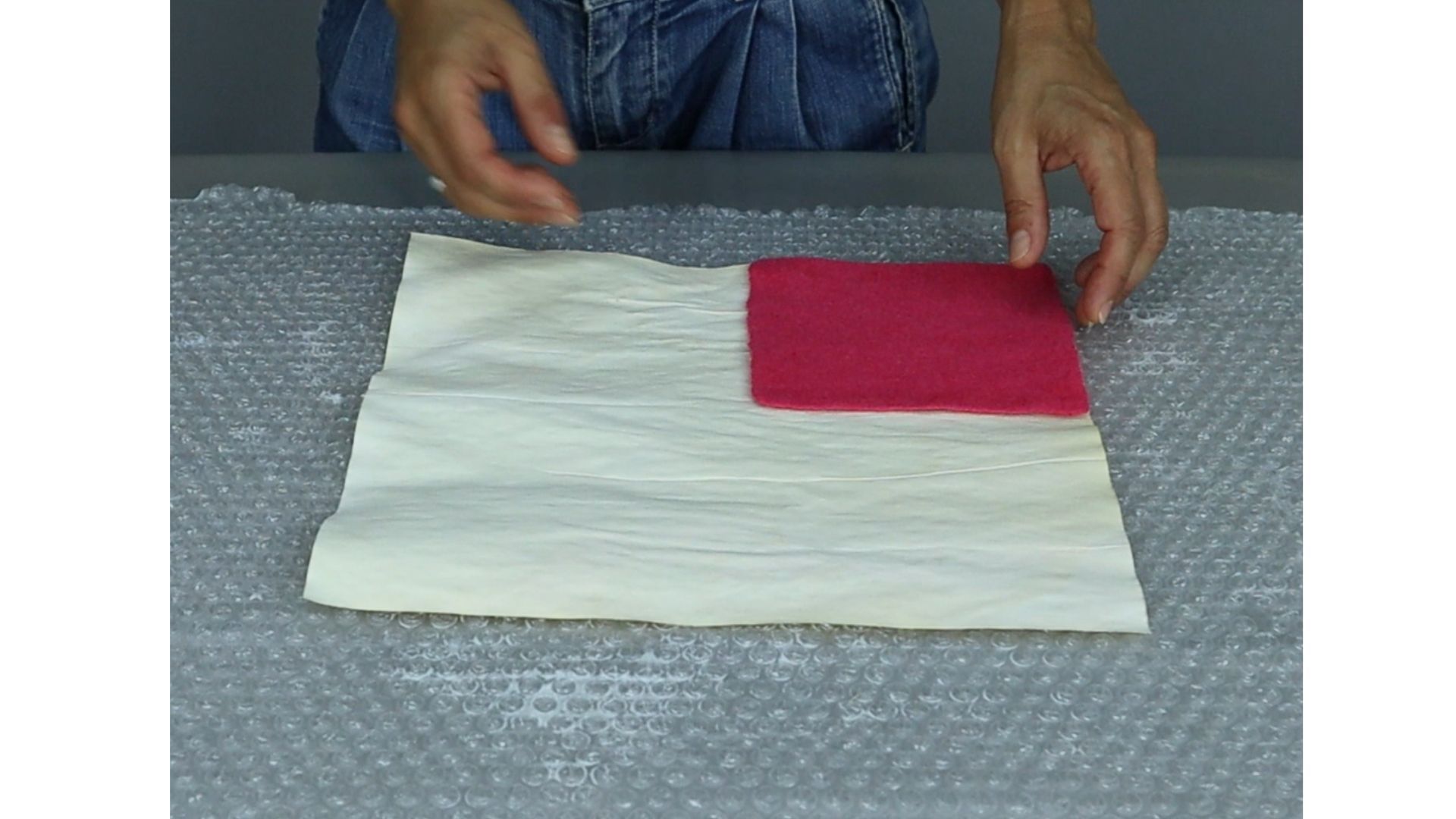

Did you know that it’s possible to wet felt without soap? It’s not very common. Most felt makers use soap to felt, but there are some who don’t.

Because I’m curious and I like to test everything, I decided to make a small sample to see how it works. You never know. Sometimes you do something in a c...

Felting and fulling methods. You’ll see different felt makers using different ones, and this may have raised the question for you: Is it really that important which ones you choose to use? I mean, they all produce felt, right?

Well, yes, I guess that’s right. But choosing the right felting and full...

Today, I want to talk to you about something that makes felt makers a little bit nervous: the S word. SAMPLES!

While I know most of us would do anything to avoid making samples before we felt a piece, I’m – once again – going to try to persuade you to make them.

Now, when we talk about making sa...

Have you ever had periods of time when you seem completely unable to have any new ideas? No good ones, no bad ones, nothing.

You sit in your studio, you tidy up, you go through your wool, through books, through images and notes you’ve been collecting for future projects, and still nothing comes up...

Like everybody else, when I first started wet felting, I didn’t have a style or a voice. I wasn’t even thinking about having one. I was just trying to figure out how I could make the pieces I saw others do and, above all, understand how wool behaves.

If that’s where you are right now, know that eve...

Is there anything more discussed in wet felting than how to get the shrinkage you want? I don’t think so. And it’s kind of obvious, isn’t it? I mean, if wool felts by shrinking, we need to know how much it’ll shrink. Right?

The problem is so many factors influence shrinkage. So, it can all feel ove...

After experimenting with wet felting for some time, learning the basics and maybe even felting some pieces on a resist, you may feel you’d like your felt to become more professional and well finished. Yet, you may also not know what to do to get to that next level of quality you’d like to achieve.

...In the last couple of weeks, I’ve been making big pre-felt sheets for a piece I’m working on. And every single one of them has given me problems felting.

This can happen for several reasons. It either has something to do with the amount of soap or water, or with the temperature. When this happens, ...

When we start wet felting, there is so much to learn about the many techniques that fit under this wider umbrella, that this alone can be enough for felt makers to focus on, without ever taking a deep dive into the attributes of the fibers from different sheep breeds.

So, often it’s people who have...

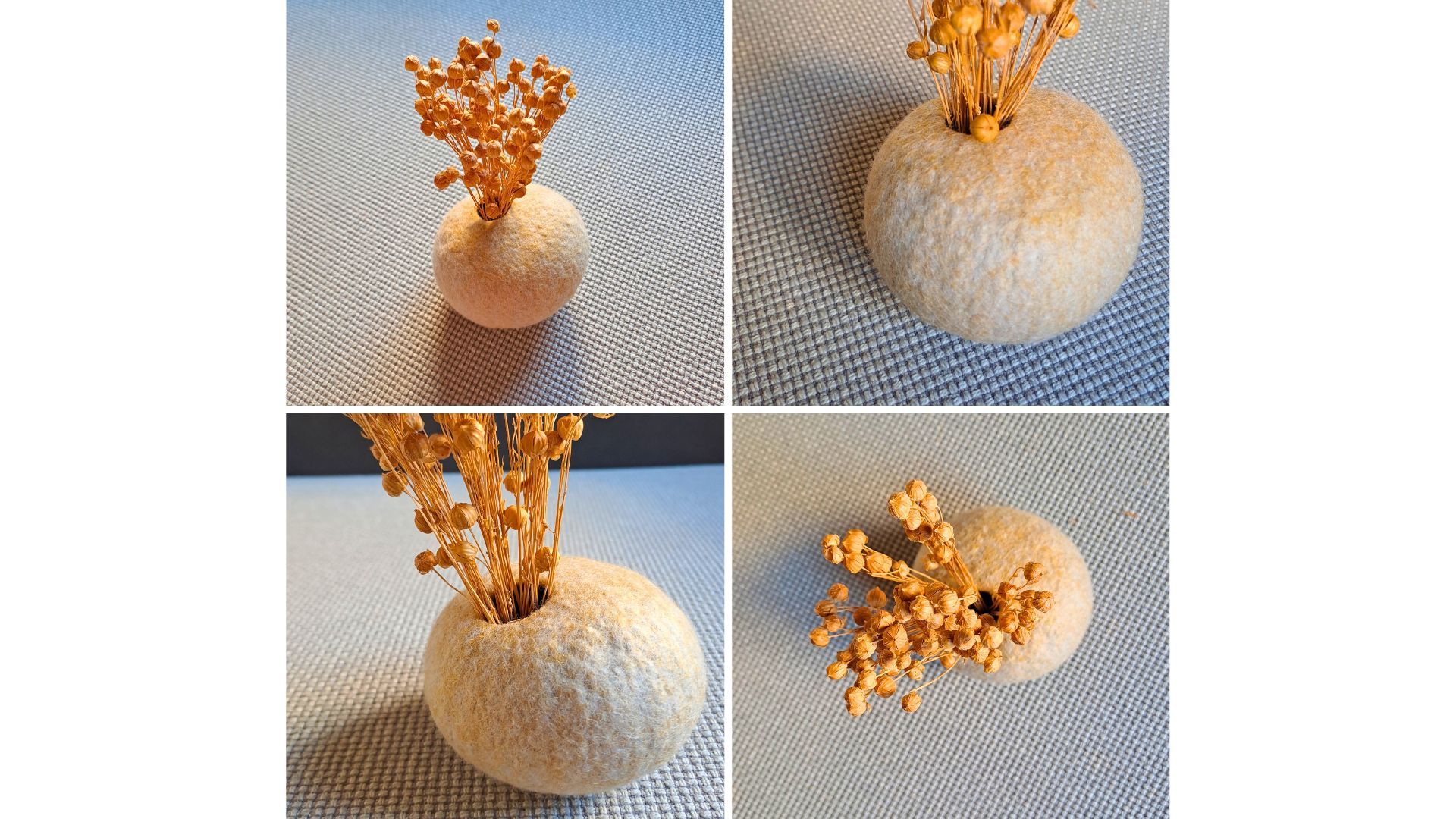

I don’t use stiffeners often. But sometimes they can be useful, especially for sculptural wet felting. The problem with stiffeners is finding one that doesn’t make your work very hard, and still lets your felt look natural.

As in many other aspects of felt making, there are different opinions about...

If you were among the people who read last week’s post about the book “Schafwolle verarbeiten” and thought: “Ya, looks great, Vanda. But what will I do with a book in German?”, I’ve got you covered.

I’ve just received another book on wool I had ordered recently. This time in English. And I can assu...

You may know that for many years I’ve had a list of suppliers for wool and wet felting equipment that I offer in my courses and as a download on my website. It’s based on my own experience buying wool online, as well as on recommendations from students and followers.

Whether new felt makers email m...