The Dodo Blog

If you’ve been waiting for the registration to THE DODO HUB to open, I’ve got good news. You can now sign up here.

WHO IS THE PROGRAM FOR?

You’ve been a felt maker for some years now, but …

- you feel like you’ve reached a plateau, and you don’t know how to develop your work further;

- you wan...

We start wet felting because we’re fascinated by the material and the possibilities of creating all sorts of things, from wearables to sculpture ✨💫

We see what others are doing, so we dream of what we’d like to create. But, let’s face it, wool can be stubborn, and the initial phases aren’t easy.

...It’s finally here, the new format I’ve been mentioning for some time!

So, what is it exactly? If you’ve been following my blog or Instagram account, you’ve heard about THE DODO HUB for sure. Chances are you're curious about TDH and you’d like to know more about it.

Since it’s a one-year program, i...

Is there anything more discussed in wet felting than how to get the shrinkage you want? I don’t think so. And it’s kind of obvious, isn’t it? I mean, if wool felts by shrinking, we need to know how much it’ll shrink. Right?

The problem is so many factors influence shrinkage. So, it can all feel ove...

After experimenting with wet felting for some time, learning the basics and maybe even felting some pieces on a resist, you may feel you’d like your felt to become more professional and well finished. Yet, you may also not know what to do to get to that next level of quality you’d like to achieve.

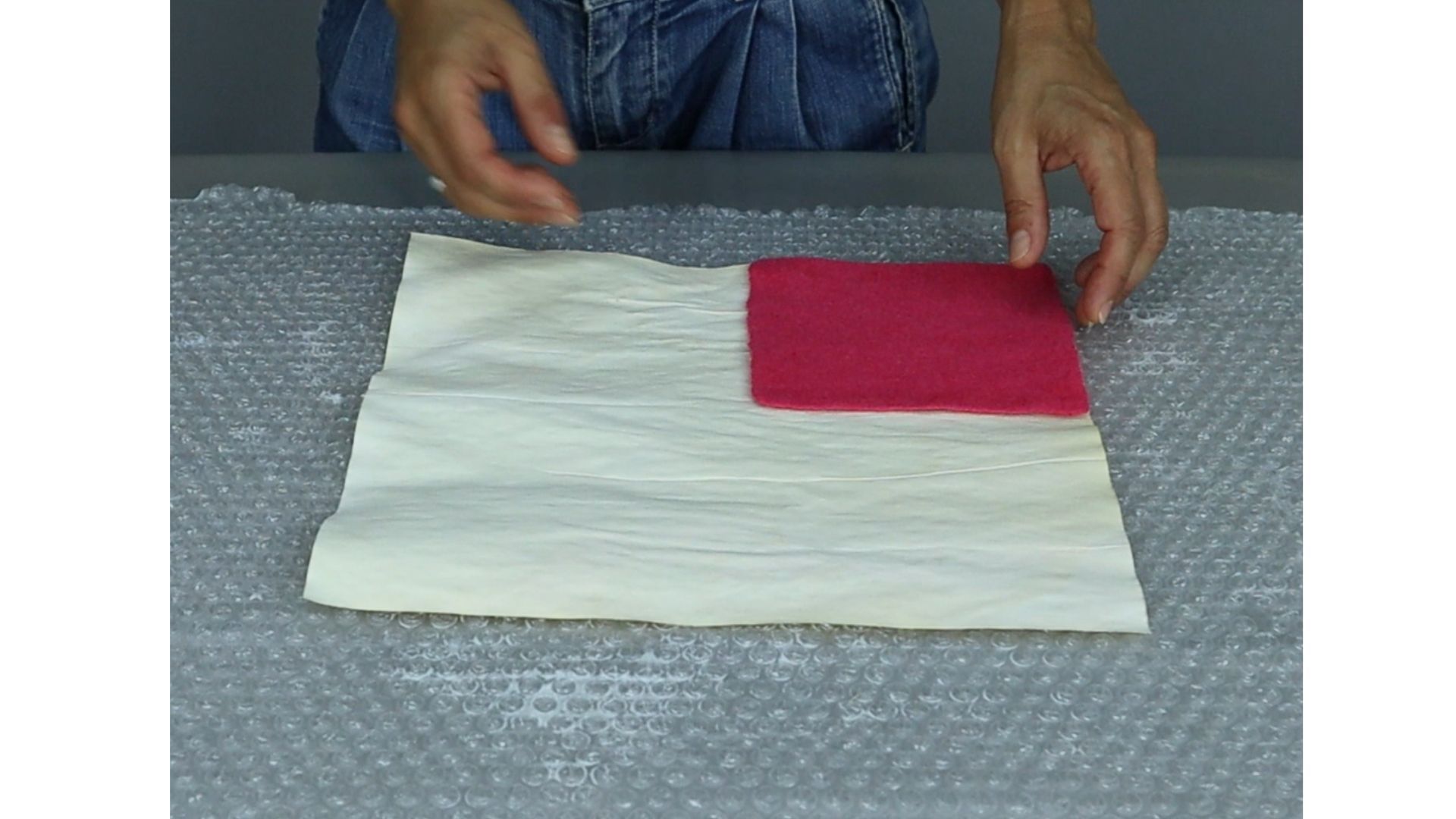

...This video is the first one of a new series, in which we’ll be looking into the topic of making cords or ropes in wet felting.

While it’s more geared towards beginner felt makers, I know that many more experienced people also struggle with this. During my years as a felting teacher, I’ve gotten man...

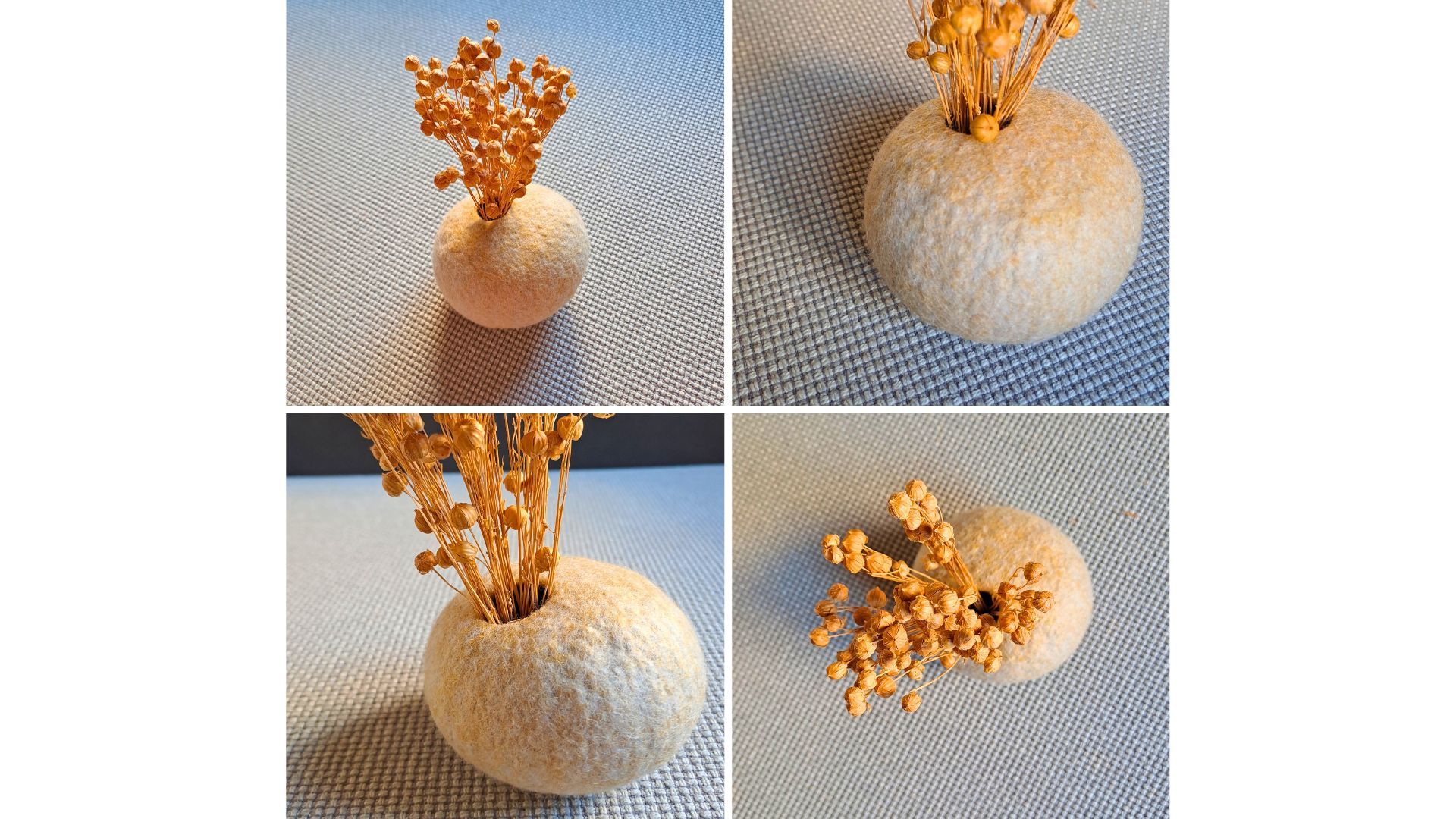

So you had a look at the program, and now you’re thinking “Yes, one technique a month. But what do we really felt inside THE DODO HUB?”

I get that it may not be totally clear to you, so let me help you with that.

First, above there's a short video of some of the beautiful pieces made by the partic...

If you’ve been waiting to enroll in THE DODO HUB, I’ve got good news! The registration is open as of now.

Are you new to the DODO world, and not sure what THE DODO HUB is?

- It’s a comprehensive year-long program designed to take you from the intermediate level to an advanced and independent ...

Have you ever felted a vessel, a bag or another 3D item and found that you couldn’t get rid of the seams on the sides? Did you wonder why it happened? Did you think that those seams could have been prevented by filling the piece with a balloon or any other object?

If that’s the case, know that the ...

I’m working on a new class that is meant to help felt makers go all the way (smoothly) from total beginner to intermediate. If you’ve recently started wet felting or you’ve been felting for a while, but still feel like there are many gaps in your knowledge, this may be for you.

But I’ll need some t...

I’ve often been asked for tips on how to wet felt when you have health issues like back pain or arthritis.

Personally, I’ve also dealt with pain that was either caused or worsened by the strain I’ve put on my body due to wrong postures during wet felting.

It’s irrefutable that felting is a very ph...

Are you having issues getting your wet felted bowl to have a perfectly round shape? Or maybe you’ve felted a flat round piece, but, after fulling, it doesn’t look like a circle anymore? Your layout may be the cause of this distortion.

Wet felting doesn’t have many rules, so it allows for different ...