The Dodo Blog

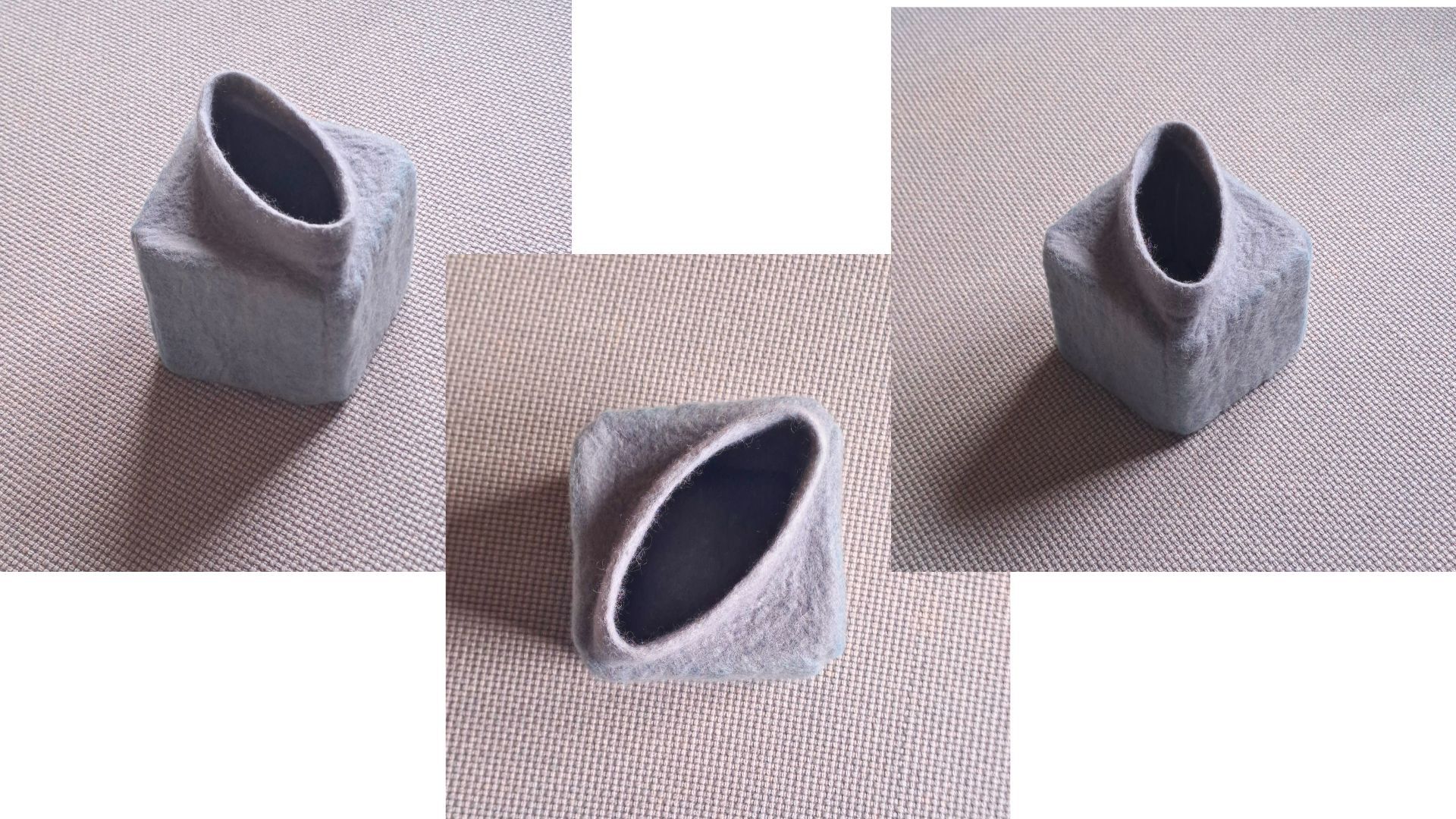

Did you know that it’s possible to wet felt without soap? It’s not very common. Most felt makers use soap to felt, but there are some who don’t.

Because I’m curious and I like to test everything, I decided to make a small sample to see how it works. You never know. Sometimes you do something in a c...

Looking for a new creative challenge?

I’ve got you covered!

Until Sunday, October 5th, get the class STAR ANISE SEED POD for only 99€. That’s 30€ off the regular price!

This is an exclusive offer for newsletter subscribers. So, if you’re on the email list, please check your inbox for this special...

Wet felting contributes to our well-being and it can even be therapeutic. It’s been used in the Waldorf method for a long time to cultivate the connection to Nature through a natural material, to engage the senses, develop fine motor skills, concentration and creativity in children.

If you’ve been ...

We’ve started a little tradition in The Dodo Hub: once a month we hop online and felt together. Lately, the challenge has been about the circle. We grab a round resist, and experiment with the techniques from the program.

You can felt anything you’d like to try, as long as you start with that circl...

I’ve spent years felting berets and trying to get them to be soft and wearable. Along the way, I tested materials, methods, and fiber ratios until I found what I was looking for.

The course FELTING SOFT HATS – THE BERET distills those experiments, based on trial and error, into a clear, practical ...

If you’ve ever wet felted a beret, you might relate to this frustration: no matter how thinly you lay out your wool, the result turns out too stiff; even with fine merino, the beret never really drapes the way you want.

I know, because I went through the same thing for years.

That got me into a lo...

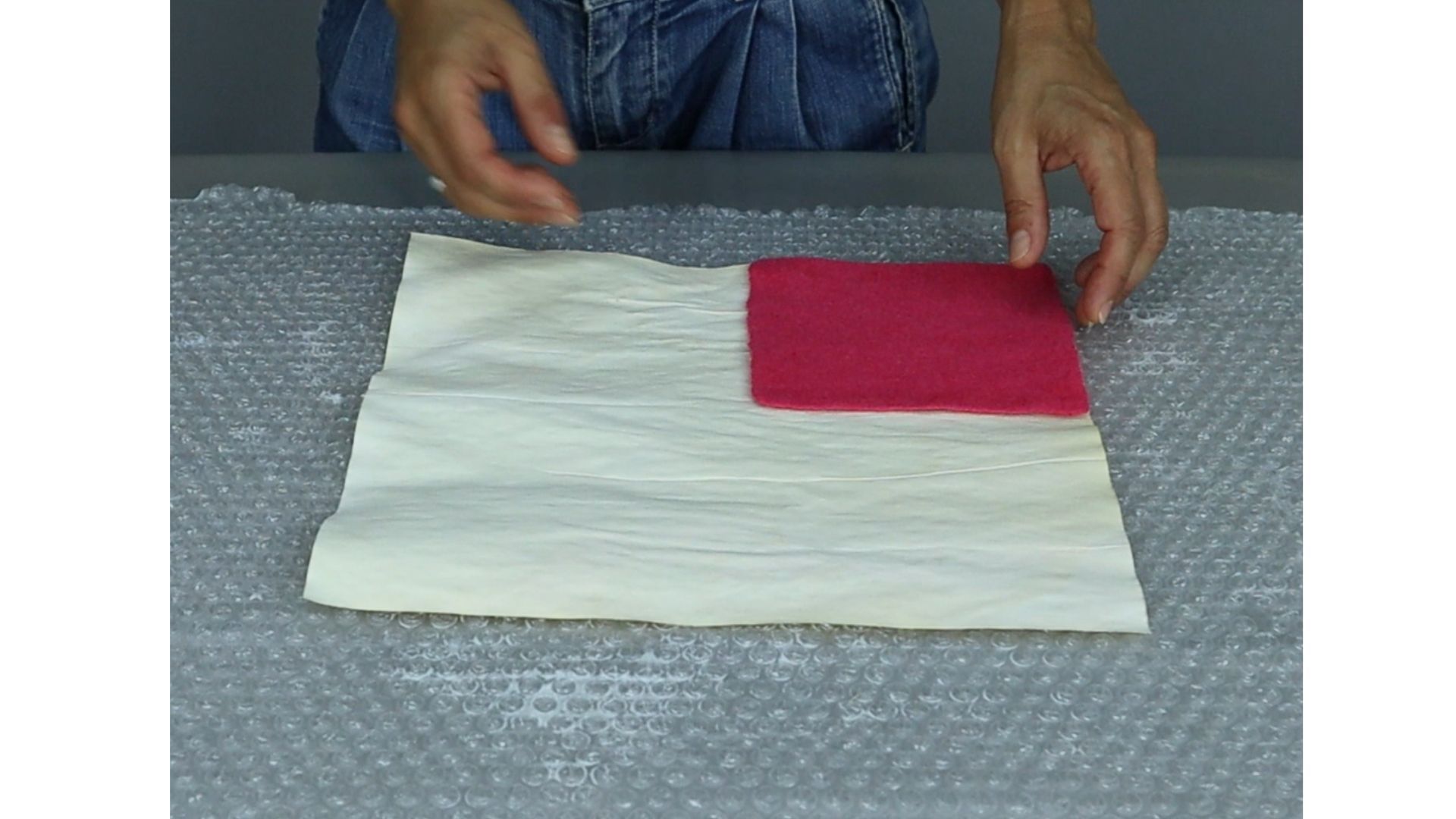

Today, I want to talk to you about something that makes felt makers a little bit nervous: the S word. SAMPLES!

While I know most of us would do anything to avoid making samples before we felt a piece, I’m – once again – going to try to persuade you to make them.

Now, when we talk about making sa...

If you’ve been waiting for the registration to THE DODO HUB to open, I’ve got good news. You can now sign up here.

WHO IS THE PROGRAM FOR?

You’ve been a felt maker for some years now, but …

- you feel like you’ve reached a plateau, and you don’t know how to develop your work further;

- you wan...

We start wet felting because we’re fascinated by the material and the possibilities of creating all sorts of things, from wearables to sculpture ✨💫

We see what others are doing, so we dream of what we’d like to create. But, let’s face it, wool can be stubborn, and the initial phases aren’t easy.

...It’s finally here, the new format I’ve been mentioning for some time!

So, what is it exactly? If you’ve been following my blog or Instagram account, you’ve heard about THE DODO HUB for sure. Chances are you're curious about TDH and you’d like to know more about it.

Since it’s a one-year program, i...

Like everybody else, when I first started wet felting, I didn’t have a style or a voice. I wasn’t even thinking about having one. I was just trying to figure out how I could make the pieces I saw others do and, above all, understand how wool behaves.

If that’s where you are right now, know that eve...

Is there anything more discussed in wet felting than how to get the shrinkage you want? I don’t think so. And it’s kind of obvious, isn’t it? I mean, if wool felts by shrinking, we need to know how much it’ll shrink. Right?

The problem is so many factors influence shrinkage. So, it can all feel ove...